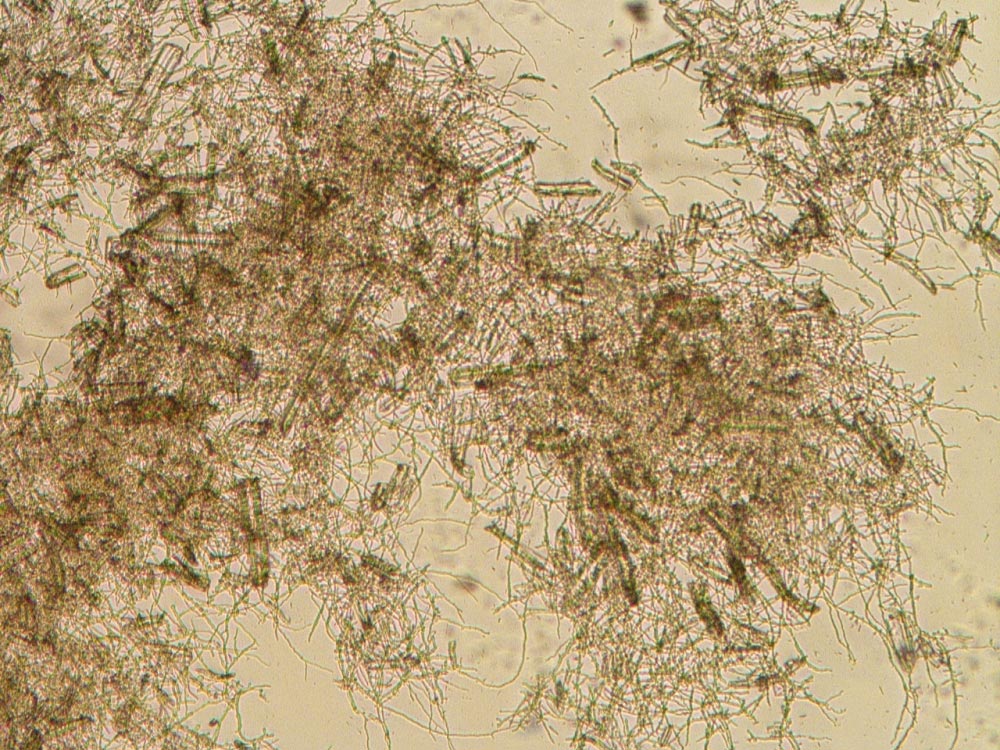

Trichoderma reesei fungus RUT-C30 rigidity, which turn out to be engineered to provide high-yield enzymes. Credit rating: LNBR-CNPEM

Brazilian researchers feeble genetic engineering to manufacture a low-cost platform for the production of enzymes that ruin down sugarcane trash and bagasse for conversion into biofuel. The recent molecules maintain many doable industrial good points.

Researchers at the Brazilian Center for Learn in Energy and Materials (CNPEM) maintain genetically engineered a fungus to provide a cocktail of enzymes that ruin down the carbohydrates in biomass, equivalent to sugarcane trash (tops and leaves) and bagasse, into fermentable sugar for industrially efficient conversion into biofuel.

The constructing of low-cost enzyme cocktails is one among the fundamental challenges in producing 2d-era ethanol.

2d-era biofuels are manufactured from various styles of nonfood biomass, including agricultural residues, wooden chips, and ruin cooking oil. The CNPEM study group’s course of paves the style for optimized use of sugarcane residues to provide biofuels.

The fungus Trichoderma reesei is one among basically the most prolific producers of plant cell wall-degrading enzymes and is widely feeble in the biotechnology commerce. To pink meat up its productivity as a biofactory for the enzyme cocktail in predict, the researchers launched six genetic adjustments into RUT-C30, a publicly available rigidity of the fungus. They patented the technique and reported it in a chunk of writing revealed in the journal Biotechnology for Biofuels.

“The fungus turn out to be rationally modified to maximize production of those enzymes of biotechnological interest. The use of the CRISPR/Cas9 gene-enhancing technique, we modified transcription components to administer the expression of genes linked to the enzymes, deleted proteases that triggered complications with the steadiness of the enzyme cocktail, and added crucial enzymes the fungus lacks in nature. Due to this, we were ready to enable the fungus produce a considerable amount of enzymes from agroindustrial ruin, a cost-effective and plentiful feedstock in Brazil,” Mario T. Murakami, Scientific Director of CNPEM’s Biorenewables Laboratory (LNBR), educated Agência FAPESP.

Some 633 million a full bunch cane are processed per harvest in Brazil, yearly generating 70 million metric a full bunch cane trash (dry mass), in maintaining with the National Meals Present Company (CONAB). This ruin is underutilized for gas ethanol production.

Murakami stressed out that nearly the general enzymes feeble in Brazil to decompose biomass are imported from a couple of foreign producers that take the skills below commerce secret safety. In this context, the imported enzyme cocktail can boom as noteworthy as 50% of a biofuel’s production cost.

“Below the long-established paradigm, a protracted time of research were wished to manufacture a competitive enzyme cocktail production platform,” he acknowledged. “Moreover, the cocktails couldn’t be got utterly by artificial biology ways from publicly available traces for the reason that producers feeble diversified concepts to manufacture them, equivalent to adaptive evolution, exposing the fungus to chemical reagents, and inducing genomic mutations in focus on in self assurance to set up basically the most attention-grabbing phenotype. Now, alternatively, thanks to developed gene enhancing tools equivalent to CRISPR/Cas9, we’ve succeeded in setting up a competitive platform with apt a couple of rational adjustments in two and a half years.”

The bioprocess developed by the CNPEM researchers produced 80 grams of enzymes per liter, the most sensible seemingly experimentally supported titer as a lot as now reported for T. reesei from a low-cost sugar-based fully feedstock. Here’s more than double the concentration beforehand reported in the scientific literature for the fungus (37 grams per liter).

“A attention-grabbing facet of this study is that it wasn’t confined to the lab,” Murakami acknowledged. “We examined the bioprocess in a semi-industrial production ambiance, scaling it up for a pilot plant to evaluate its financial feasibility.”

Even supposing the platform turn out to be customized for the production of cellulosic ethanol from sugarcane residues, he added, it would possibly most likely ruin down other styles of biomass, and developed sugars would perhaps also be feeble to provide other biorenewables equivalent to plastics and intermediate chemical substances.

Novel enzyme class

The technique turn out to be the good consequence (when it comes to an industrial utility) of large-ranging study performed by LNBR to manufacture enzymes in a position to breaking down carbohydrates. In one other survey supported by FAPESP and revealed in Nature Chemical Biology, the researchers revealed seven recent enzyme classes level to above all in fungi and micro organism.

The recent enzymes belong to the glycoside hydrolase (GH) household. In step with Murakami, these enzymes maintain essential doable for good points no longer apt in the realm of biofuels nonetheless also in medication, meals processing and textiles, to illustrate. The enzymes will encourage recent industrial processes by leveraging the diversified concepts wherein nature decomposes polysaccharides (carbohydrates made up of many straightforward sugars).

These enzymes ruin down beta-glucans, some of basically the most plentiful polysaccharides level to in the cell walls of cereals, micro organism and fungi, and a large piece of the enviornment’s available biomass, indicating the enzymes’ doable use in meals preservatives and textiles. Within the case of biofuels, the fundamental property is their ability to digest arena topic rich in vegetable fibers.

“We web web screech online out to survey nature’s differ in degrading polysaccharides and the plan in which this info would perhaps also be applied to processes in diversified industries,” Murakami acknowledged. “As well to the invention of recent enzymes, one other crucial facet of this study is the similarity network contrivance we use to provide systematic and profound info of this enzyme household. The contrivance enabled us to start from scratch and in a barely short time, arrive at basically the most studied household of enzymes active on beta-1,3-glucans as a lot as now, with info available on specificity and motion mechanisms.”

The key criterion for classifying enzymes is in total phylogeny, i.e., the evolutionary ancient previous of the molecule, whereas CNPEM researchers focal level on functionality.

“Thanks to advances in DNA sequencing skills, we’ve many identified genetic sequences and a successfully-established ability to survey and signify molecules and enzymes when it comes to their functionality. Due to this, we’ve been ready to refine the similarity network methodology and use it for the first time to survey enzymes active on polysaccharides,” Murakami acknowledged.

The use of the similarity network contrivance, the group classified seven subfamilies of the enzymes in maintaining with functionality. Characterizing no longer much less than one member of every subfamily, the researchers accessed in systematic terms the differ of molecular concepts for degrading beta-glucans contained in thousands of participants of the enzyme household.

Biochemical tour de power

Phylogenetic evaluation specializes in DNA areas that had been conserved over time, whereas classification by functionality is in maintaining with nonconserved areas linked to purposeful differentiation. “This gave us efficiency and enabled us to group more than 1,000 sequences into only seven subgroups or classes with the identical feature,” Murakami acknowledged.

For the reason that contrivance turn out to be recent, the researchers performed loads of other study to double-take a look at and validate the classification technique. From the seven teams of enzymes in a position to degrading polysaccharides, they got 24 fully recent constructions, including various substrate-enzyme complexes, view-about essential in offering info to wait on realize the motion mechanisms sharp.

The survey comprised purposeful and structural analyses to admire how these enzymes act on the carbohydrates concerned. “Polysaccharides reach in dozens of configurations and are in a position to many styles of chemical bonds,” Murakami acknowledged. “We wished to jog attempting exactly which chemical bonds and architectures are acknowledged by every enzyme. For this motive, it needed to be a multidisciplinary survey, combining structural and purposeful files supported by evaluation the usage of mass spectrometry, spectroscopy, mutagenesis and diffraction experiments to elucidate the atomic constructing.”

Within the “Files & Views” piece of the identical whisper of Nature Chemical Biology, Professor Paul Walton, Chair of Bioinorganic Chemistry at the College of York in the UK, rated the glycoside hydrolase survey a “biochemical ‘tour de power’” for its revolutionary contrivance and praised its “enormous insights”, including that the researchers were “ready to precise and isolate exemplars from every class [of enzymes] to jog attempting whether the differences in sequences between the classes were reflected in their constructions and activities.”

References:

“Structural insights into β-1,3-glucan cleavage by a glycoside hydrolase household” by Camila R. Santos, Pedro A. C. R. Costa, Plínio S. Vieira, Sinkler E. T. Gonzalez, Thamy L. R. Correa, Evandro A. Lima, Fernanda Mandelli, Renan A. S. Pirolla, Mariane N. Domingues, Lucelia Cabral, Marcele P. Martins, Rosa L. Cordeiro, Atílio T. Junior, Beatriz P. Souza, Érica T. Prates, Fabio C. Gozzo, Gabriela F. Persinoti, Munir S. Skaf and Mario T. Murakami, 25 Might maybe well maybe 2020, Nature Chemical Biology.

DOI: 10.1038/s41589-020-0554-5

“Enzymes knuckle down to the job” by Paul H. Walton 17 June 2020, Nature Chemical Biology.

DOI: 10.1038/s41589-020-0585-y

“Rational engineering of the Trichoderma reesei RUT-C30 rigidity into an industrially relevant platform for cellulase production” by Lucas Miranda Fonseca, Lucas Salera Parreiras and Mario Tyago Murakami, 22 Might maybe well maybe 2020, Biotechnology for Biofuels.

DOI: 10.1186/s13068-020-01732-w

Leave a comment

Sign in to post your comment or sign-up if you don't have any account.